William Northrop | Northrop Sales INC. | Phone: 904-285-4940 | wmnorthrop@earthlink.net

Casting, Machining and Stamped Components

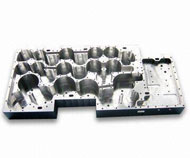

CNC Machined Parts

COMMERCIAL MACHINING

40 CNC Milling and Turning Machines ranging from Verticals, Horizontals and Multi-Axis Turning Centers

CNC Machining Centers: MILLING

- Mazak Double Pallet Vertical Machining Centers - 59”x 31”

- Mazak Horizontal Machining Centers - 42”x 31”x 32”

- Matsuura Double Pallet Vertical Machining Centers - 29”x 17”

- Mori Seiki Horizontal Machining Centers - 24”x 23”x 25”

- Brother’s Double Pallet Vertical Machining Centers - 21” x 13”

- Miyano Vertical Machining Centers, 4-Axis capability - 12” x 8 “

- Fanuc M-16 Robots with Vision Systems

- Matsurra 5 Axis Machining Center - 24”x 18”

- Kitamura Horizontal CNC Machining Centers

CNC TURNING CENTERS

Up to 32” X 10” Work piece envelope

Mazak Quick Turn 8N CNC Lathe

Mori Seiki SL200, Turning Centers with Bar Feeder

CNC HAAS Servo Controlled 8” Rotary Table

Mazak Quick Turn 10SQU Turret Lathe

Hitachi Seiki 20SII with Bar Feed

Miyano 8- Axis CNC Turning Center - 2” Bar capacity

Gildemeister Twin 65 CNC Lathe 2-1/2” Bar capacity with 8” Chuck capacity

8 Citizen Swiss CNC Turning Machines – 5 to 7 Axis to 1-5/8” capacity

ONE STOP SERVICE FOR:

- Machining

- Assembly

- Painting

- Plating

- Welding

- Grinding

- Heat-Treating

- Kitting

- Direct Shipping

MATERIALS:

- Aluminum

- Steel

- Stainless Steel

- Brass

- Bronze

- Copper

- Plastics

- Cast Iron

- Exotic Materials

- Composite Materials plus additional Materials

QUALITY CONTROL:

- Temperature Controlled Inspection Room

- CMM – Coodinate Measuring Machines

- Complete Gauging Inspection Program

- Bar Code Routing

- Additional Equipment

FMS LINES – Flexible Manufacturing Systems

- 6 Makino Horizontal Machining Centers with Rail Systems

- 8 Pallets

- Spindle Speeds up to 20,000 RPM’s- Work piece envelope 22”x 22”x 22”

- 4 Makino Horizontal Machining Centers - 34 Pallets – Up to 15,000 RPM – Work piece envelope 36”x 22”x 22”

- 4 Makino Horizontal Machining Centers with Rail Systems - 44 Pallets - Up to 12,000 RPM - Work Piece 35”x 35”x 35”

- Additional CNC Machining Centers available

SERVICES INCLUDE: In-House

- Complete Tool Room

- NADCAP Chemical Processing accreditation for our Paint and Chromate Conversion Line in-house.

- Painting, Part Marking, Hardware and Helicoil Installation as well as Assembly, Silk Screen

- Painting: CARC and Conductive Spray Coating in house.

- Welding: Mil-Spec and Commercial MIG/TIG/Robotic

- Water Jet up to 8” Thick

- Robotic Deburring System

QUALITY and INSPECTION: IN-HOUSE and OUTSIDE LABS

- Multiple CNC CMM w/Auto Probe Changer

- Profile Projector

- Magnetic Particle Tester and Dye Penetrate Inspection

- Salt Spray Cabinet

- Leak Testing

- Air Leak Test Cell

- Gages and Measuring Instruments

- SPC

- Profilimeter Surface Analyzing Instrument

- Hardness Tester

- Additional Inspection Equipment